High-efficiency and Low-cost

Gradient material composite manufacturing and repair

High efficiency and low cost

Compared to forging, wire material utilization rate is high, greatly reducing the user's raw material cost, especially for precious metal materials. Compared to LMD forming, arc forming deposition has high efficiency and low equipment hardware cost.

Superior mechanical properties

It has significant advantages in terms of maximum printing size, flexibility, mechanical properties of printed parts, pre-processing requirements, available materials, and printing costs.

Multi-heat source synchronous operation

Optional MIG, TIG, CMT, and PA (plasma) single welding machines or combinations of multiple welding machines as heat sources. Compared to LMD forming, energy sources can be used for high reflectivity materials such as aluminum alloys, copper alloys, etc.

Gradient material composite manufacturing and repair

It has the ability to manufacture and repair gradient material composites using multiple wire materials, with quick design responsiveness, suitable for customized manufacturing of small batches, gradient materials, and multi-variety products.

Project Name | Parameters and Descriptions | |

Build Dimension(X×Y×Z) | 2500mm×2500mm×1500mm | |

XYZ-Axis Positioning Accuracy | 0.1mm | |

XYZ-Axis Repeat Positioning Accuracy | 0.08mm | |

XYZ-axis maximum positioning speed | 5m/min | |

Dual-Axis Rotary Table (optional) | Disc Diameter | Φ650 mm |

Swing Range | ±90° | |

Rotation Range | n×360° | |

Turntable Load Capacity | Horizontal 500kg / Vertical 400kg | |

Purification System | Air-washing & Filtration Cycle | |

Oxygen Content | ≤50 ppm | |

Smoke Purification | Independent Explosion-proof Fan | |

Power Supply Type | TIG/MIG | |

Welding Current | TIG current 5-700A/MIG power supply 3-400A | |

Control System | 828D SL | |

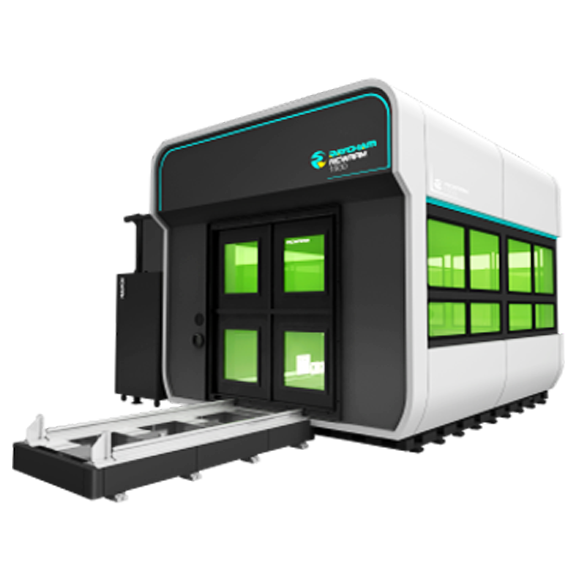

Mainframe Size | 5100mm×4700mm×4300mm | |

Mainframe Weight | 38 T | |