High efficiency and low cost

High flexibility and large processing range

Integration of manufacturing and repair

High flexibility

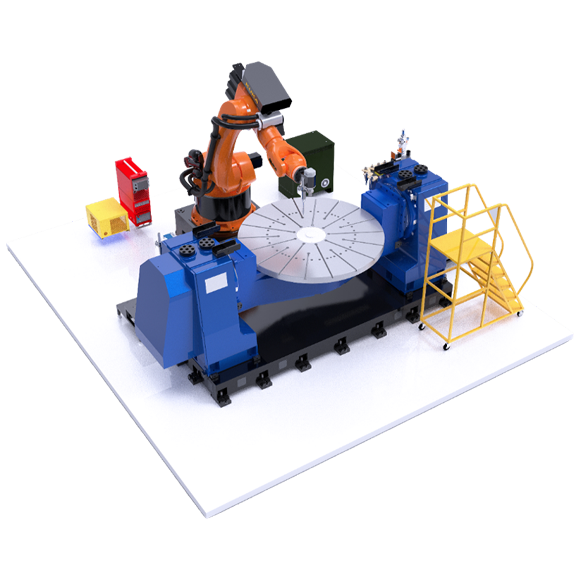

6-axis heavy-duty robot & 2-axis positioner robot flexible laser/arc metal additive and subtractive manufacturing equipment solution.

Large format

Workbench size φ2000mm, maximum load 2 tons, and maximum part forming size φ2000mm*1000mm.

Strong adaptability

Suitable for printing a variety of materials such as aluminum alloy, iron-based alloy, cobalt-based alloy, and nickel-based alloy.

High efficiency

Compared with ordinary laser powder forming, the efficiency is improved by 3-5 times.

Dual-energy beam

Equipped with a new high-temperature stable processing head and tool quick-change device, it can realize laser/arc dual energy beam additive and subtractive processing composite manufacturing.

Intelligence

It can realize dynamic closed-loop feedback control of the molten pool and equipment fault diagnosis and warning, and trace the processing process.

Project Name | Parameters and Descriptions | |

Build Dimension | Diameter2000*1000mm | |

Maximum load capacity | 2000kg | |

Major Equipments Size | 4700*5000*4000mm | |

Major equipments Weight | 12T | |

Supporting Software | Self-developed Additive&Subtractive Material Path Planning Software | |

Arc Additive Manufacturing System | Maximum Additive Forming Efficiency:900cm³/h | |

Welding Current Range:MIG/MAG3-400A;Welding Rod:10-400A | ||

Laser Powder Feeding 3D Printing System | Forming Efficiency:120-350cm³/h | |

Laser Power:4-10KW | ||

Powder Utilization Rate:70%--80% | ||

Subtractive Processing System | Milling Spindle Rated Power(S1/S6):8.5/10KW | |

Milling Spindle Rated Torque(S1/S6):6.7/8 N/m | ||

Subtractive Tool Magazine Capacity: 6 tools. |