Targeting small and medium-sized complex structures,

such as turbine blades, turbine outer rings,

small combustion chambers, CVD diamond, cutting tools, etc.

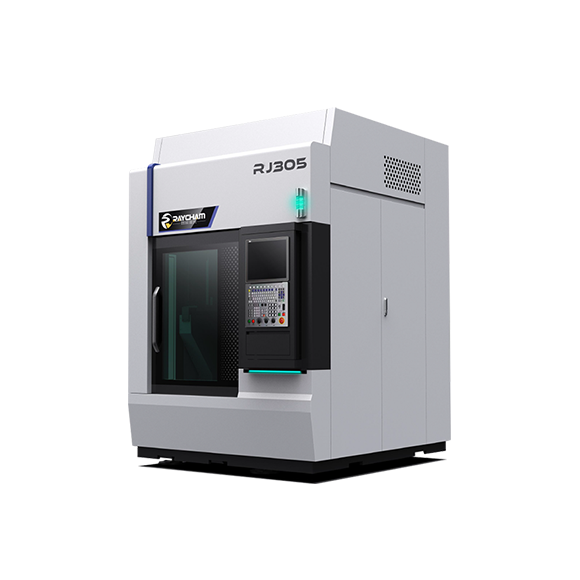

The RJ305 water-guided laser processing equipment features a marble-cast mineral bed, direct-drive motors, high-precision transmission components, and sub-micron grating, equipped with a domestic five-axis CNC system. The entire machine is assembled in a temperature-controlled environment with a ±1°C tolerance. The equipment's linear repeat positioning accuracy reaches the national standard of 3μm (or JIS standard ±1μm).

Smooth Surface

The cutting surface is smooth, with minimal thermal deformation and thermal damage.

Simple Operation

With a large working distance, focusing is not required.

Fast and Accurate

High processing precision, narrow kerf width, and the ability to cut 1.6mm PCD and tungsten carbide at a speed of 3mm/min.

Straight Kerf

No taper, sharp edges, and completely parallel kerf.

System | Project Name | Parameters and Specifications |

Optical System | Laser Type | Nd:YAG,pulsed |

Wavelength nm | 532 | |

Average Power W | 200 | |

Fiber Core Diameter μm | Φ200 | |

Water Cooling System | Water Pressure Stability bar | ±5 |

Water Pressure bar(max) | 500 | |

Nozzle Diameter μm | 50-100 | |

Motion System | Processing Range (Including Fixtures) mm | Φ260×260(5-axis) 350×430×350(3-axis) |

A-axis Rotation Range ° | -120~+20 | |

C-axis Rotation Range ° | N×360 | |

X/Y/Z-axis Positioning Accuracy μm | 5(ISO) | |

X/Y/Z-axis Repeat Positioning Accuracy μm | 3(ISO) | |

Table Size mm | Φ300 | |

Table Load Capacity kg | 300/150(90°) | |

CNC System | Huazhong 848 Five-Axis Linkage | |

Dimensions and Weight | Equipment Dimensions(W×D×H)mm | 1930×2050×2770 |

Optical and Water Assembly Cabinet Dimensions(W×D×H)mm | 700×1800×1720 | |

Equipment Weight kg | 5500 | |

Optical and Water Assembly Cabinet Weight kg | 700-750 |