Ultra-thin coating

high efficiency

replacing electroplating

High-speed laser cladding technology can replace traditional electroplating processes, mainly targeting failure components such as hydraulic pillars, piston rods, cylinders, feed rollers, printing drums, cooling rollers, and transmission shafts to enhance the performance of new products and repair the surfaces of failed components. This technology improves the service life of workpieces and extends the maintenance cycle of the entire equipment. The equipment is easy to operate, has high cladding efficiency, low coating dilution rate, and forms a metallurgical bond with the substrate. The bonding strength is much higher than that of electroplated layers. It is mainly used in industries such as coal mining, machinery manufacturing, oil drilling, paper printing, and food industry.

integrated design, easy operation;

high cladding efficiency, stable quality;

low coating dilution rate, metallurgical bonding;

low heat input, controllable deformation;

low coating roughness, minimal machining allowance.

Project Name | Parameters and Descriptions |

Laser power | 6000W |

Spindle speed | 0.1~350rpm |

Machine load | 3000kg |

X-axis stroke | 3000mm |

Y-axis stroke | 200mm |

Z-axis stroke | 400mm |

Clamping diameter of workpiece | 50~630mm |

Clamping length of workpiece | 2500mm |

Powder Feeder | Pneumatic Powder Feeder |

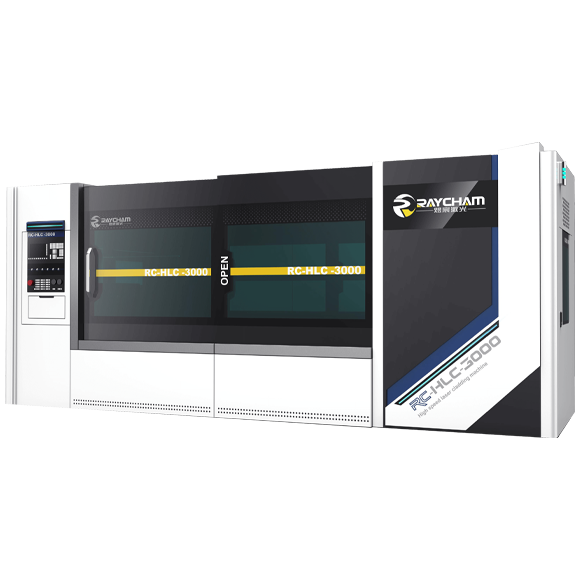

Protective Sheet Metal | Fully enclosed structure |