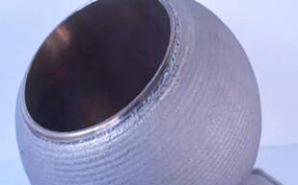

Broadband and high-efficiency cladding

Integrated casting bed

Stable and reliable

Mainly used for hydraulic support products

By emitting a laser beam through a high-power laser, the circular spot is converted into a rectangular spot by an optical mirror group. The rectangular spot has high efficiency, and the gravity powder feeder ensures uniform and stable powder feeding. The powder feeding width matches the size of the rectangular spot. The laser beam acts on the surface of the substrate to form a wide melting pool, which solidifies and metallurgically combines with the substrate, forming a wide cladding layer with excellent performance.

Broadband and high-efficiency cladding:

- Integrated casting bed, stable and reliable

- Prompt and considerate after-sales service, ensuring production

- Common process data package, ready to use

- Mature process system can pass the 9-level salt spray test

- Continuous powder feeding module, uninterrupted cladding process for individual workpieces

- Intelligent control and fault diagnosis system, easy to learn and use.

Project Name | Parameters and Descriptions |

Laser power | 6000W |

Laser cladding head | Spot 14×3mm |

Spindle speed | 0.1~350rpm |

Machine load | 3000kg |

X-axis | 3000mm |

Y-axis | 200mm |

Z-axis | 400mm |

Clamping diameter of workpiece | 150~630mm |

Clamping length of workpiece | 2500mm |

Powder Feeder | Gravity Powder Feeder |

Protective Sheet Metal | Semi-closed Structure |