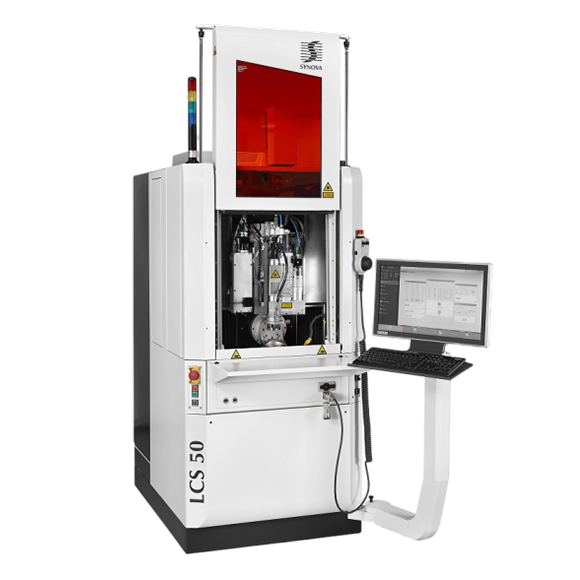

The LCS 50 is ideal for finish-machining of diamond tools, watch components and other small work pieces that require precision cutting, drilling, grooving or slicing as well as 3D processing.

Ordering EquipmentSharp and Smooth

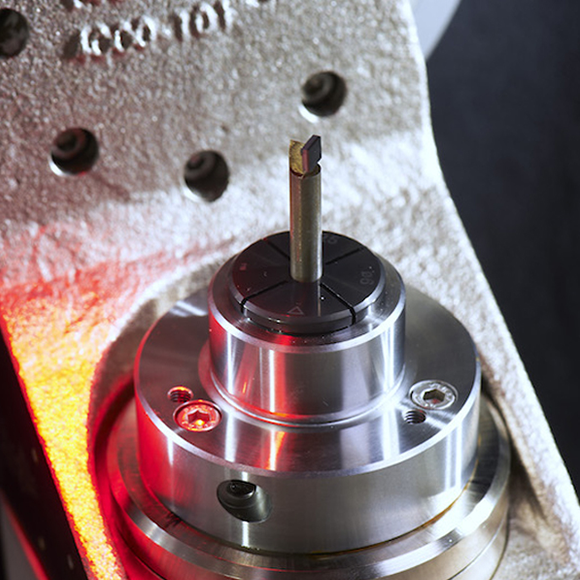

Cylindrical beam resulting in parallel kerfs (no V-shape)

Smooth cutting surfaces and sharp edges (Ra as low as 0.15 μm)

Virtually no heat impact thanks to water jet cooling capability

Fast and Accurate

Finnish cutting of 1.6 mm PCD and cemented carbide in up to 5 mm/min. No limit in thickness.

High mechanical precision with a tolerance of less than +/- 3 μm

Very small kerf width (down to 30 μm)

Clean and Easy

Clean surfaces and no depositions

No or very little post treatment required

No focus control necessary due to long working distance

Version | LCS 50-3 | LCS 50-5 |

Working volume mm (W x D x H) | 50 x 50 x 50 | 50 x 50 x 50 |

Accuracy (after compensation) µm | +/- 3 | +/- 3 |

Repeatablility µm | +/- 1 | +/- 1 |

Number of axes | 3-axis | 5-axis |

Laser Type | Diode pumped solid state Nd: YAG, pulsed | Diode pumped solid state Nd: YAG, pulsed |

Wavelength nm | 532 | 532 |

Dimensions machine mm (W x D x H) | 800 x 1200 x 1650 | 800 x 1200 x 1650 |

Dimensions cabinet mm (W x D x H) | 700 x 2300 x 1600 | 700 x 2300 x 1600 |

Materials | Hard materials: Polycrystalline CBN (PcBN), polycrystalline diamonds (PCD), monocrystalline diamonds (MCD), chemical-vapor-deposition (CVD) diamonds, natural diamond (ND), tungsten carbide (WC) Metals: Stainless steel, Durnico, CuBe, copper, brass, aluminum, shape-memory alloys (Nitinol), titanium, nickel, super alloys etc. Ceramic: Zirconia (ZrO2), LTCC (low-temperature co-fired ceramic), Aluminum-nitride (AlN), Aluminum-oxide (Al2O3) | |