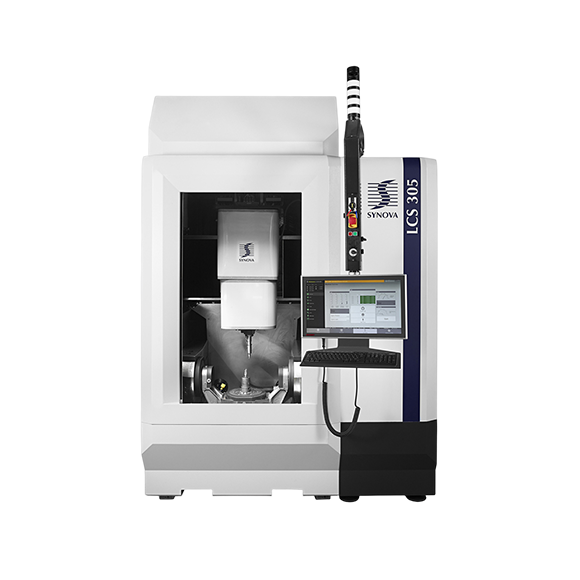

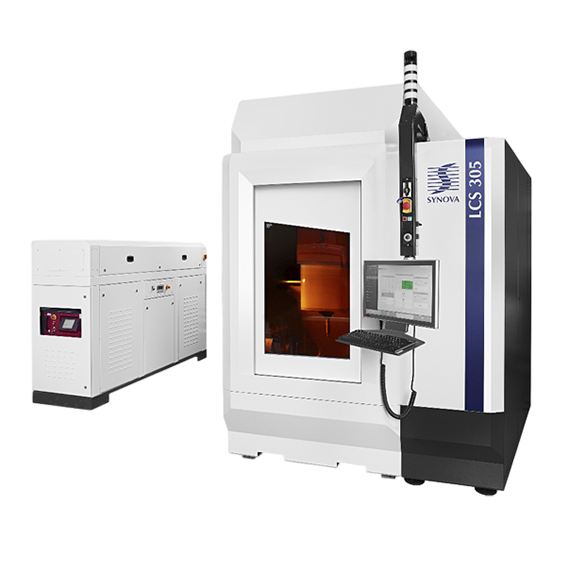

The LCS 305 with 5 axes is specifically designed for the automatic production of larger and multi-tooth diamond cutting tools. The CNC machine with five synchronous axes is characterized by a particularly intelligent machine concept and highly dynamic axe

Ordering EquipmentSharp and Smooth

Smooth cutting surfaces and sharp edges (Ra as low as 0.2 μm)

Cylindrical beam resulting in parallel kerfs (no V-shape)

Virtually no heat impact thanks to water jet cooling capability

Fast and Accurate

Finnish cutting of 1.6 mm PCD and cemented carbide in 3 mm/min.

High mechanical precision with a tolerance of +/- 5 μm

Very small kerf width (down to 30 μm)

Clean and Easy

Clean surfaces and no depositions

No post treatment required

No focus control necessary due to long working distance

Version | LCS 305 |

Maximum stroke mm (W x D x H) | 500 x 380 x 380 |

Accuracy* (after compensation) µm | +/- 5 |

Repeatability* µm | +/- 2 |

Number of axes | 5-axis |

Laser Type | Diode pumped solid state Nd: YAG, pulsed |

Wavelength nm | 532 |

Dimensions machine mm (W x D x H) | 1800 x 1950 x 2610 |

Dimensions cabinet mm (W x D x H) | 700 x 2300 x 1600 |

| Materials | Hard materials: Polycrystalline CBN (PcBN), polycrystalline diamond (PCD), single crystalline diamond (SCD), chemical-vapor-deposition (CVD) diamond, natural diamond (ND), tungsten carbide (WC) Metals: Superalloys, stainless steel, aluminium, copper, titanium, nickel etc. Ceramics: Ceramic-matrix composites (CMCs), silicon carbide (SiC), silicon nitride (SiN), zirconia (ZrO2), HTCC/LTCC (high temperature and low temperature co-fired ceramic), aluminum nitride (AlN), aluminum oxide (Al2O3) |

| * only if temperature controlled room | |