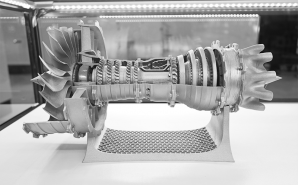

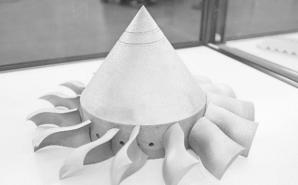

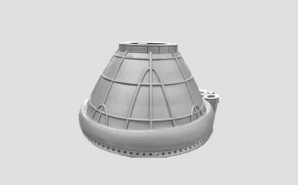

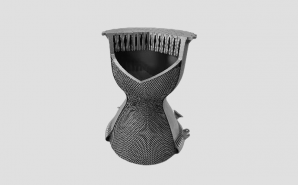

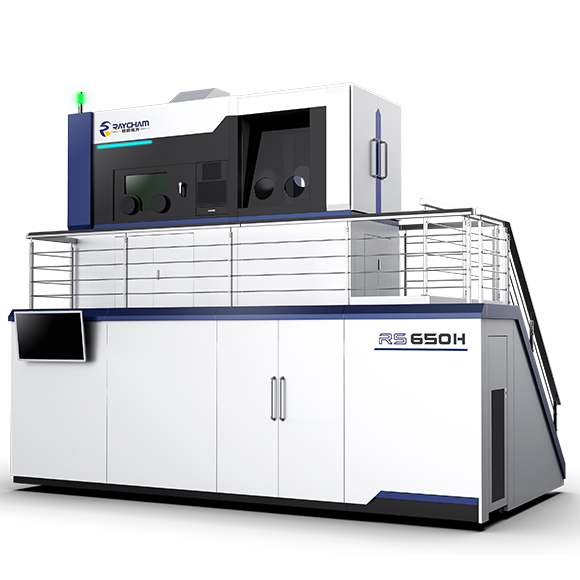

Suitable for high-performance 3D printing requirements

of large-scale aerospace and other industries.

Efficient Laying Powder

The RS650H device has the function of single/dual-direction powder spreading. Dual-direction powder spreading reduces time wasted by the scraper's return stroke and reduces the time for single-layer powder spreading. The device is equipped with dual lasers, doubling the forming efficiency. For complex and fine parts, single-direction powder spreading can be selected to improve printing accuracy.

Precision Motion

The accuracy of the device's Z-axis directly affects the dimensional accuracy, mechanical properties, and surface roughness of the formed parts. The Z-axis motion mechanism of the RS650H device uses a servo motor, combined with a precision ball screw + absolute position grating ruler, to form a closed-loop control. This ensures long-term stable and high-precision operation of the Z-axis motion mechanism.

Multiple Safety Interlocks

The RS650H device uses reliable electrical components and a well-designed safety circuit interlock mechanism to improve the safety of the equipment. The safety circuit of the equipment consists of safety relays, high-quality emergency stop buttons, and safety door locks, forming various safety circuits.

Efficient Backflush Filtration

The RS650H device comes standard with a backflush filtration system, equipped with a three-stage filtration. The filter element can be automatically cleaned, and it is equipped with three F9-grade filter elements. During the printing process, two filter elements can be replaced without stopping the machine while one is in use. The single filter element has a service life of 1800 hours, maintaining stable and efficient filtration effects, ensuring a safe and controllable forming process. The compact modular design and safety measures ensure the stable operation of the equipment for a long time.

Quick Atmosphere Cleaning

The RS650H device innovatively adopts a multi-stage segmented atmosphere cleaning mode. Multi-point air intake can simultaneously replace the gas in the forming chamber and the atmosphere circulation pipeline, accelerating the cleaning speed and effectively shortening the cleaning time. It achieves an equipment forming environment with an oxygen content below 1000ppm within 45 minutes.

Atmosphere Balance Mode

The RS650H device uses a combination of mechanical piping and signal control to achieve atmospheric communication between the forming chamber, the upper and lower spaces of the forming cylinder, and the powder hopper and other enclosed spaces. Combined with dynamic electrical signal control, it maintains pressure balance and consistent oxygen content at various positions in the sealed space of the equipment, eliminating phenomena such as powder leakage and spillage.

Powder Circulation Treatment

The RS650H device is equipped with a specialized powder circulation treatment system, integrating functions such as powder deposition, powder collection, powder sieving, and powder storage. This system minimizes direct contact between workers and powder, reduces the labor intensity of manual powder addition, improves the safety factor of the powder addition process, realizes online powder addition by the host machine, and can recycle the excess powder from the equipment's operation process. It is an environmentally friendly, labor-friendly, energy-saving, and reliable auxiliary equipment.

Fully Enclosed Part Removal

The RS650H device is equipped with a specialized powder removal box for quick and convenient removal of residual powder from the formed parts. The design of the multi-choice powder suction device can adapt to different structures of the formed parts and strive to remove residual powder from narrow gaps or internal holes of the parts, improving the efficiency of powder removal. The fully enclosed removal environment ensures the safety of operators and cleanliness of the workshop.

One-Button Transfer Function

The RS650H device is equipped with a "one-button transfer" function, which allows quick and stable switching between the "forming station" and the "part removal station" of the forming cylinder, improving the reliability of equipment operation.

Data Monitoring

The RS650H device is equipped with the company's self-developed RC-Standard-SLM software, which provides process data packages for various mature materials, allowing for easy import and one-click printing function for user convenience.

Convenient Operation

The RS650H device is equipped with the company's self-developed RC-Argus-SLM software, which provides necessary support for realizing an intelligent factory-level quality control mode for the metal additive manufacturing process, including "intelligent recognition, preset processing, remote control, and human assistance".

Open Source Equipment

The RS650H device provides users with various editable functions such as laser power, scanning speed, stripe width, scanning direction, upper and lower surfaces, and fan frequency.

Project Name | Parameters and Descriptions |

Maximum Forming Size | 650mm×650mm×1100mm(include Basilar Plate) |

Laser Power | 4x500W Single-mode Fiber Laser(Four lasers) |

Laser Beam Quality | M2≤1.2 |

Overlapping Accuracy | ≤0.05mm |

Maximum Scanning Speed | ≥7.0m/s |

Powder Layer Thickness | 20~100μm |

Powder Layering Method | two-way laying powder |

Provided Powder Layering Method | Falling powder from above |

Working Atmosphere | Argon |

Minimum Oxygen Content | ≤100ppm |

Highest Substrate Preheating Temperature | Maximum heating temperature of heating film 200℃ |

Processing File Format | Job |

Working Forming Accuracy | ≤0.1mm |

Control Method | RC-ROS-SLM |

Power Supply and Power | Three-phase 380V,50/60Hz,≤45Kw |