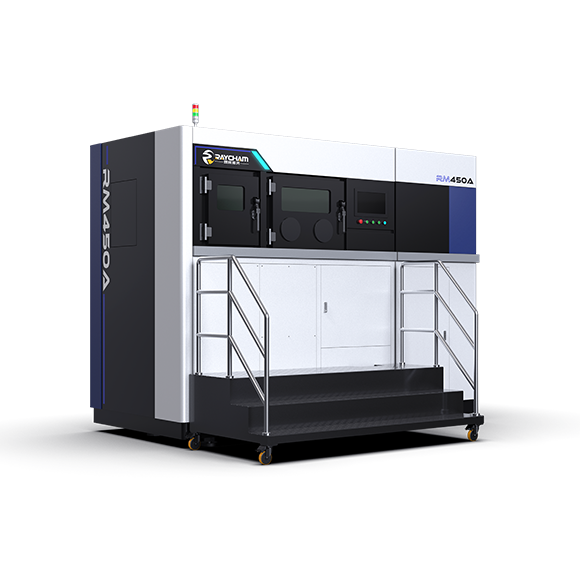

Suitable for 3D printing requirements of medium-sized parts

in civil industry, molds, and other fields.

Excellent performance in comprehensive operation andmaintenance costs: Suitable for industrial product production.

Efficient and secure: Adopting high-efficiency dual laserprinting and equipped with a three-level filtering system, it can achieve automatic blowback and has strong safety.

Open source process parameters: Equipped with an industrial specific precision printing process parameter packageit can achieve small pores and fine patterns.

Project Name | Parameters and Descriptions |

Maximum Forming Size | 440mm×440mm×500mm |

Laser Power | 500W Single-mode Fiber Laser(Optional Dual Laser) |

Laser Beam Quality | M2≤1.2 |

Overlapping Accuracy | ≤0.05mm |

Maximum Scanning Speed | ≥7.0m/s |

Powder Layer Thickness | 20~100μm |

Powder Layering Method | Intelligent Single Direction |

Powder Feeding Mode | Down Feed Type |

Gas Requirement | Ar or N2 |

Forming Accuracy | ≤0.1mm(When Dimension>100mm,The Forming Accuracy is ≤0.1%) |

Highest Substrate Preheating Temperature | Room Temperature +20~200℃ |

Power Supply and Power | Three-Phase 380V,50Hz,≤25Kw |