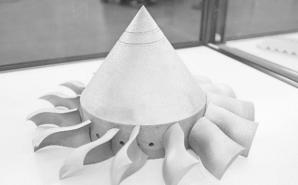

Suitable for high-end 3D printing requirements

in aerospace and other industries.

Stable Optical Path

The independent optical path support structure ensures the stability and reliability of the optical path system, providing a high-quality laser beam. The daily operation of the equipment does not affect the beam, reducing the need for beam adjustment work. The equipment is equipped with dual lasers, with a large overlapping area of the forming surface, doubling the forming efficiency.

Precise Motion

The accuracy of the equipment's Z-axis directly affects the dimensional accuracy, mechanical properties, and surface roughness of the formed parts. The RS450D equipment's Z-axis motion mechanism uses a servo motor and a precision ball screw to ensure long-term stable and high-precision operation of the Z-axis motion mechanism. It is also equipped with a high-precision grating ruler to further guarantee the motion accuracy of the Z-axis.

Multiple Safety Interlocks

Reliable electrical components and a well-designed safety circuit interlock mechanism are adopted to improve the safety of the equipment. The safety circuit of the equipment consists of safety relays, high-quality emergency stop buttons, and safety door locks to form various safety circuits.

Efficient Backflush Filtration

A three-stage filtration system is equipped, with the F9 level (intermediate filtration) equipped with a backflush filtration system. The filter element can be automatically backflushed and cleaned to maintain stable and efficient filtration, ensuring a safe and controllable forming process. The compact modular design and safety assurance ensure the stable operation of the equipment for a long time.

Sturdy Equipment Structure

Heavy-duty industrial-grade steel structure is adopted, and the main frame has sufficient rigidity. In addition to facilitating the installation of equipment functional modules, the space structure is compact, occupying a small footprint, and facilitating overall transportation and on-site installation and commissioning.

Data Monitoring

Equipped with the company's self-developed RC-Standard-SLM software, it provides process data packages for various mature materials, which can be easily imported and operated by users with one-click printing function.

Convenient Operation

The company's self-developed RC-Argus-SLM software is configured to provide necessary support for realizing the intelligent factory-level quality control mode of the metal additive manufacturing process, including "intelligent recognition, preset processing, remote control, and manual assistance".

Open Source Equipment

Various editable functions are provided to users, including laser power, scanning speed, stripe width, scanning direction, upper and lower surfaces, and fan frequency.

Project Name | Parameters and Descriptions |

Maximum Forming Size | 440mm×440mm×500mm(include Basilar Plate) |

Laser Power | 500W Single-mode Fiber Laser(Optional Dual Laser) |

Laser Beam Quality | M2≤1.1 |

Overlapping Accuracy | ≤0.05mm |

Maximum Scanning Speed | ≥7.0m/s |

Powder Layer Thickness | 20~100μm |

Powder Layering Method | Intelligent Single sided Powder Layering |

Provided Powder Layering Method | Convey the powder from below |

Working Atmosphere | Argon or Nitrogen Gas |

Minimum Oxygen Content | ≤100ppm |

Highest Substrate Preheating Temperature | Room Temperature +20~200℃ |

Processing File Format | Slc |

Working Forming Accuracy | ≤0.1mm(when forming size>100mm,forming accuracy≤0.1%) |

Control Method | RC-ROS-SLM |

Power Supply and Power | Three-phase 380V,50Hz,≤25Kw |