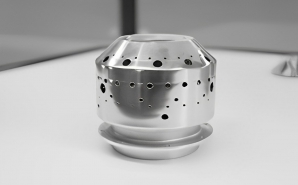

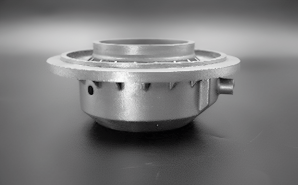

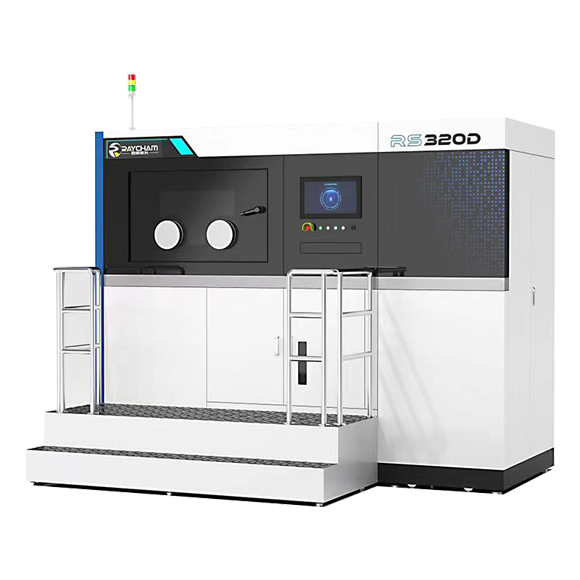

Suitable for high-performance 3D printing

requirements of small and medium-sized parts

in aerospace and other industries.

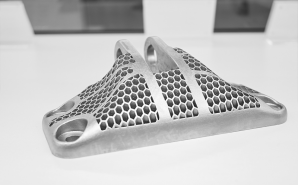

Efficient and diverse

The RS320D can be equipped with a variable zoom lens with a zoom range of 1 to 3 times, allowing adjustable beam size and providing a versatile operating space suitable for technical research and different printing strategies.

Precision movement

The Z-axis accuracy of the equipment’s forming chamber directly affects the height direction dimensions, mechanical properties, and surface roughness of the formed parts. The Z-axis motion mechanism uses a servo motor and a precision ball screw to ensure long-term stable and high-precision operation. It is also equipped with a high-precision grating ruler to further guarantee the movement accuracy of the Z-axis.

Multiple safety interlocks

The RS320D uses reliable electrical components and a well-designed safety circuit interlock mechanism to improve equipment safety. The safety circuit of the equipment consists of safety relays, high-quality emergency stop buttons, and safety door locks to form various safety circuits.

Efficient atmosphere system operation

The RS320D’s atmosphere system and main equipment have added switch valves for separate gas replacement, which speeds up the gas replacement process and shortens the printing preparation time. The F9 level filter can be replaced without stopping the machine during the printing process. After replacing the filter, the gas can be replaced separately until the working requirements are met, and then directly connected to the atmosphere system to start normal operation.

Industrial automation

The RS320D achieves non-chamber powder feeding through external powder addition, ensuring continuous consistency of formed parts. Additionally, it can be equipped with an automatic powder feeding system to avoid direct contact between operators and powder, making it safer, more convenient, and efficient. Combined with Zhongke Yuchen’s related control system, it can realize industrial automation production lines.

Data monitoring

The RS320D is equipped with the company’s self-developed RC-Standard-SLM software, which provides process data packages for various mature materials and allows easy import and user operation, including one-click printing function.

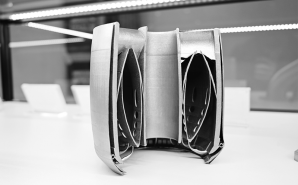

Higher efficiency

The RS320D adopts a dual laser optical system, with each galvanometer achieving full coverage of the build area, resulting in higher forming efficiency. The new powder spreading system has a short time and high efficiency.

Convenient operation

The company’s self-developed RC-Argus-SLM software provides the necessary guarantee for realizing an intelligent factory-level quality control mode for the metal additive manufacturing process, including intelligent recognition, preset processing, remote control, and manual assistance.

Open-source equipment

The RS320D provides users with various editable functions, such as laser power, scanning speed

Project Name | Parameters and Descriptions |

Maximum Forming Size | 320mm×320mm×420mm |

Laser Power | 500W Single-mode Fiber Laser(Optional Dual Laser) |

Laser Beam Quality | M2≤1.1 |

Overlapping Accuracy | ≤0.05mm |

Maximum Scanning Speed | ≥7.0m/s |

Powder Layer Thickness | 20~100μm |

Powder Layering Method | Intelligent Single sided Powder Layering |

Provided Powder Layering Method | Down Feed Type |

Working Atmosphere | Argon or Nitrogen Gas |

Minimum Oxygen Content | ≤100ppm |

Highest Substrate Preheating Temperature | Room Temperature +20~200℃ |

Processing File Format | Job |

Working Forming Accuracy | ≤0.1mm(when forming size>100mm,forming accuracy≤0.1%) |

Power Supply and Power | Three-phase 380V,50Hz,≤13kW |