process data packages

One-click access to process data packages for commonly used materials such as titanium alloys, nickel-based alloys, and steel.

Support for 240 hours of continuous operation

Through long-term optimized design assessment, it has solved problems such as thermal protection, dust protection, and wear resistance, and supports 240 hours of continuous operation.

Balance efficiency and precision

Equipped with four-way and annular nozzles, it balances efficiency and precision. The processing head has good convergence, does not clog powder, and is stable and reliable. It supports 2-tube, 5-tube, or 6-tube powder feeders, and can realize parts printing, precision repair, and high-throughput preparation of new materials.

Intelligent software system

The data acquisition software, fault diagnosis, and integrated control interface are easy to learn and use. Optional molten bath monitoring CCD and process simulation software are available.

Project Name | Parameters and Descriptions |

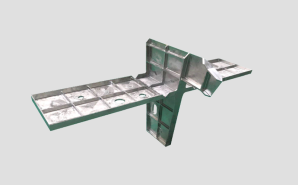

Maximum Forming Size | 1500mm*1000mm*1000mm |

X/Y/Z-Axis Positioning Accuracy | 0.08mm |

Repeated Positioning Accuracy | 0.05mm |

Clean-up System | Air-washing & Filtration Cycle |

Maximum PositioningSpeed | 5m/min |

Control System | 828D SL |

Oxygen and Water Content | ≤50ppm |

Laser Type | Fiber Laser / Semiconductor Laser |

Laser Power | 4KW/6KW |

Supporting Materials | Titanium alloy, aluminum alloy, nickel-based alloy, iron-based alloy, tool steel, stainless steel, copper alloy, low-alloy steel... |