Suitable for universities, colleges, research institutions, and other organizations.

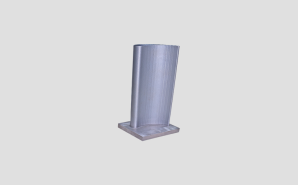

Ordering EquipmentHigh density:

The printed parts have a density of up to 99%, and their mechanical properties are superior to castings.

Shortened cycle:

It has an absolute advantage in small batches and customization, and can reduce time costs by over 60%.

Innovative design:

Design ideas are not limited by traditional manufacturing processes, making personalized design and manufacturing easy.

Environmental protection and recycling:

It can print on worn parts to repair worn areas and reuse waste parts.

Reliability:

Processing in inert gas environment ensures that active metals are not oxidized and is safe and reliable.

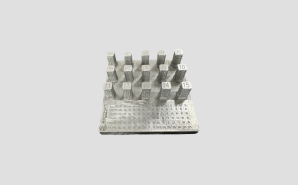

Uniqueness:

Different materials can be printed into a single sample, and a gradual change in their composition ratio can be achieved.

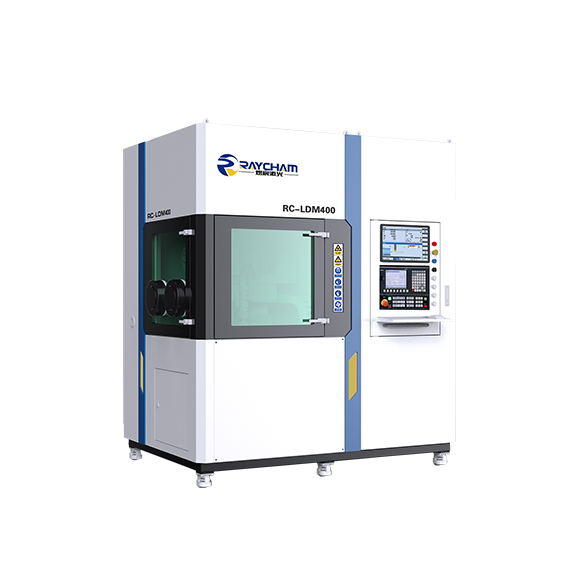

Project Name | Parameters and Descriptions |

Maximum Forming Size | 400mm*400mm*400mm |

X/Y/Z-Axis Positioning Accuracy | 0.05mm |

Repeated Positioning Accuracy | 0.03mm |

Clean-up System | Air-washing & Filtration Cycle |

Maximum PositioningSpeed | 5m/min |

Control System | NC300 |

Oxygen and Water Content | ≤50ppm |

Laser Type | Fiber Laser / Blue Laser |

Laser Power | 1KW/2KW |

Supporting Materials | Titanium alloy, aluminum alloy, nickel-based alloy, iron-based alloy, tool steel, stainless steel, copper alloy, low-alloy steel... |