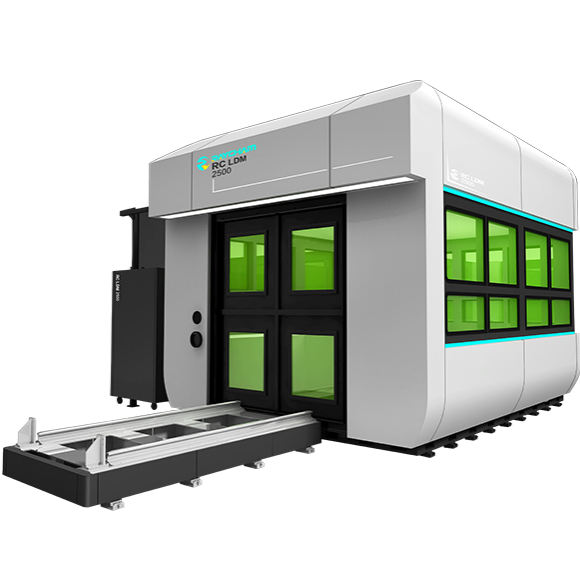

Multifunctional integration:

direct deposition forming, gradient material composite manufacturing, repair, surface strengthening, etc.

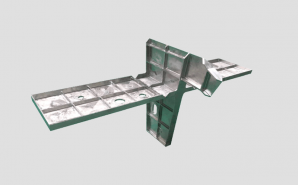

High Rigidity, High Convergence, and High Efficiency Powder Coupling Nozzle

The ten-thousand-watt high-power laser cladding nozzle independently developed by RAYCHAM is one of the most critical components to ensure the stability and reliability of additive manufacturing parts. It realizes the technology of high rigidity powder flow transportation, high precision convergence, and high efficiency utilization.

Ultra-large capacity unlimited powder replenishment module

The continuous powder feeding mechanism independently developed by RAYCHAM, with its special structural design and control principle, is connected and interacts with the powder feeder to achieve automatic powder replenishment. It does not require manual intervention and can continuously supply powder for 24 hours with one powder filling, greatly reducing the frequency of powder replenishment and replacement.

Fully automatic oxygen content self-calibration system

Oxygen content analyzers are set at different heights and different areas inside the forming chamber. The control system will collect oxygen content values in real-time and automatically calibrate the oxygen content to ensure uniformity and consistency of oxygen content in the chamber. This avoids major production losses or personal safety risks caused by data distortion or failure of a single oxygen analyzer.

Systematic safety design

Safety interlock control system, visual biological humanoid recognition technology, abnormal pressure alarm system, laser protective glass, box pressure monitoring system, environmental oxygen content monitoring system, fifth-generation explosion-proof ultra-long-life smoke and dust purification system, and various safety control measures at every stage.

Project Name | Parameters and Descriptions |

Maximum Forming Size | 2500mm*2500mm*1500mm |

X/Y/Z-Axis Positioning Accuracy | 0.1mm |

Repeated Positioning Accuracy | 0.08mm |

Clean-up System | Air-washing & Filtration Cycle |

Maximum PositioningSpeed | 5m/min |

Control System | 828D SL |

Oxygen and Water Content | ≤50ppm |

Laser Type | Fiber Laser / Semiconductor Laser |

Laser Power | 8KW/10KW |

Supporting Materials | Titanium alloy, aluminum alloy, nickel-based alloy, iron-based alloy, tool steel, stainless steel, copper alloy, low-alloy steel... |