Precision repair of small parts and in-situ preparation of

new materials/processes,

applicable to aerospace, tooling, scientific research, and various other fields.

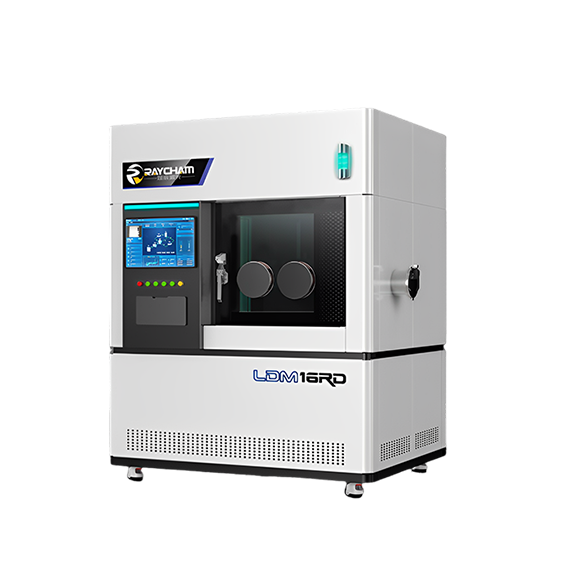

The equipment features a compact structure with a small footprint, significantly reducing floor space requirements while lowering operational and maintenance costs;

Equipped with an optional annular powder feeding or internal-laser powder feeding precision cladding head, where the internal-laser feeding technology incorporates zoom and adjustable spot size capabilities, making it ideal for thin-walled blade repairs;

The self-developed intelligent operation software RC-Argus3.0 enables real-time monitoring of equipment status, automated fault diagnostics, historical data retrieval, and multi-level access control;

The upgraded gas purification system optimizes filtration efficiency, pipeline design, and filter performance, ensuring water-oxygen content remains below 50 ppm during inert gas printing operations.

Project Name | Parameters and Descriptions |

Robot Arm Reach | 1100mm |

Positioning Repeatability | ±0.02mm |

Robot Load | 16kg |

Rotary Table Working Area | Φ125mm |

B-axis Oscillating Angle | -30°~120° |

C-axis Oscillating Angle | n×360° |

Blade Rapid Positioning | CCD Coaxial/Off-axis Camera Monitoring |

Rotary Table Maximum Load | Vertical 50kg / Horizontal 35kg |

Laser Power | 0~1000W |

Purification System | Gas Scrubbing + Recirculating Filtration |

Oxygen Content | ≤50ppm |

Cladding Head | RC-30 Annular Powder Feeding Head or CH-R20 Internal Light Powder Feeding Head (Variable Spot) |

System Security Operations and Maintenance | Argus3.0 Intelligent Operations System |

Powder Feeding Accuracy | ±2% |

Host Machine Dimensions | 1900mm×1400mm×2300mm |

Host Machine Weight | 2000kg |

Processable Material Range | Titanium Alloy, Aluminum Alloy, Nickel-Based Alloy, Iron-Based Alloy, Ceramic Powder, etc. |