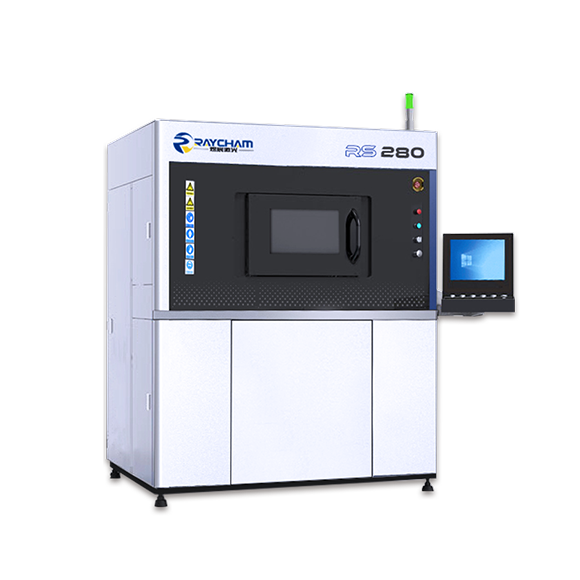

High cost-effectiveness

suitable for scientific research, industrial, and other needs

Efficient Metal Powder Laying

The RS280 device is equipped with both single and dual powder laying functions. Dual powder laying can reduce time waste caused by blade travel and reduce single-layer powder laying time. The device is equipped with dual lasers, which doubles the forming efficiency. For complex and delicate components, single powder laying can be selected to improve printing accuracy.

Precision Motion

The accuracy of the device’s Z-axis directly affects the height direction size of the formed parts, as well as the mechanical properties and surface roughness of the formed parts. The RS280 device’s Z-axis motion mechanism uses servo motors and precision ball screw to ensure stable and high-precision operation of the Z-axis motion mechanism over a long period of time.

Multiple Safety Interlocks

The RS280 device uses reliable electrical components and designs a comprehensive safety circuit interlock mechanism to improve the safety of the equipment. The safety circuit of the equipment uses safety relays, high-quality emergency stop buttons, and safety door locks to form various safety circuits.

Efficient Backflush Filtration

The RS280 device is equipped with a standard backflush filtration system, which is configured with three levels of filtration. The filter cartridges can be automatically cleaned to maintain stable and efficient filtration effects, ensuring safe and controlled forming processes. The compact modular design and safety guarantees provide long-term stable operation of the equipment.

Project Name | Parameters and Descriptions |

Maximum Forming Size | 280mm×280mm×350 mm |

Laser Power | 500W Single-mode Fiber Laser(Optional Dual Laser) |

Laser Beam Quality | M2≤1.2 |

搭 接 精 度 | ≤0.05mm |

Maximum Scanning Speed | ≥7.0m/s |

Powder Layer Thickness | 20~100μm |

Powder Layering Method | Intelligent Single/Double-sided Powder Layering |

Provided Powder Layering Method | Convey the powder from below |

Working Atmosphere | Argon or Nitrogen Gas |

Minimum Oxygen Content | ≤100ppm |

Highest Substrate Preheating Temperature | Room Temperature +20~200℃ |

Processing File Format | Slc |

Working Forming Accuracy | ≤0.1mm(when forming size>100mm,forming accuracy≤0.1%) |

Control Method | RC-ROS-SLM |

Power Supply and Power | 200-240V single-phase power supply,50/60Hz |